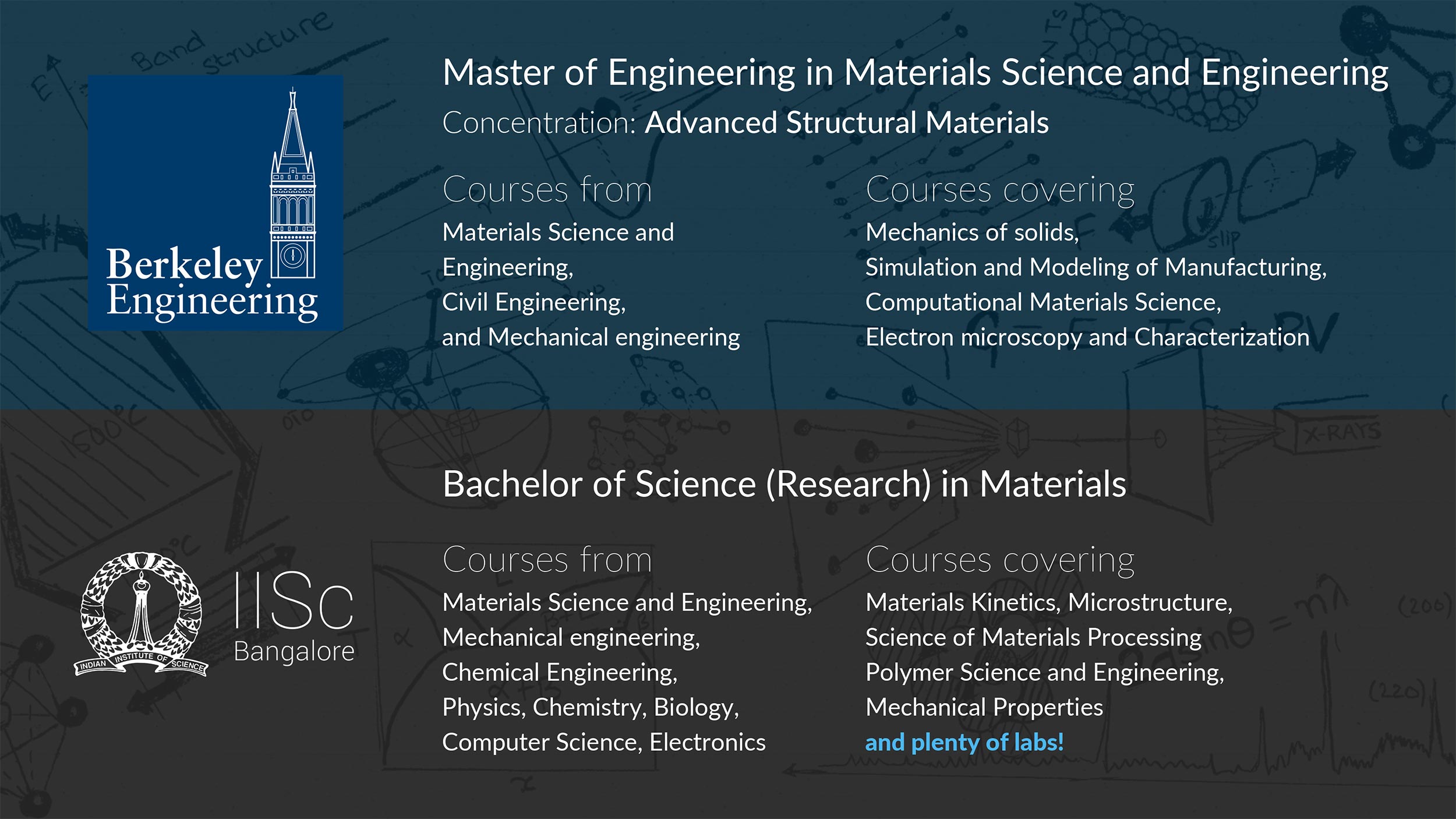

Coursework highlights

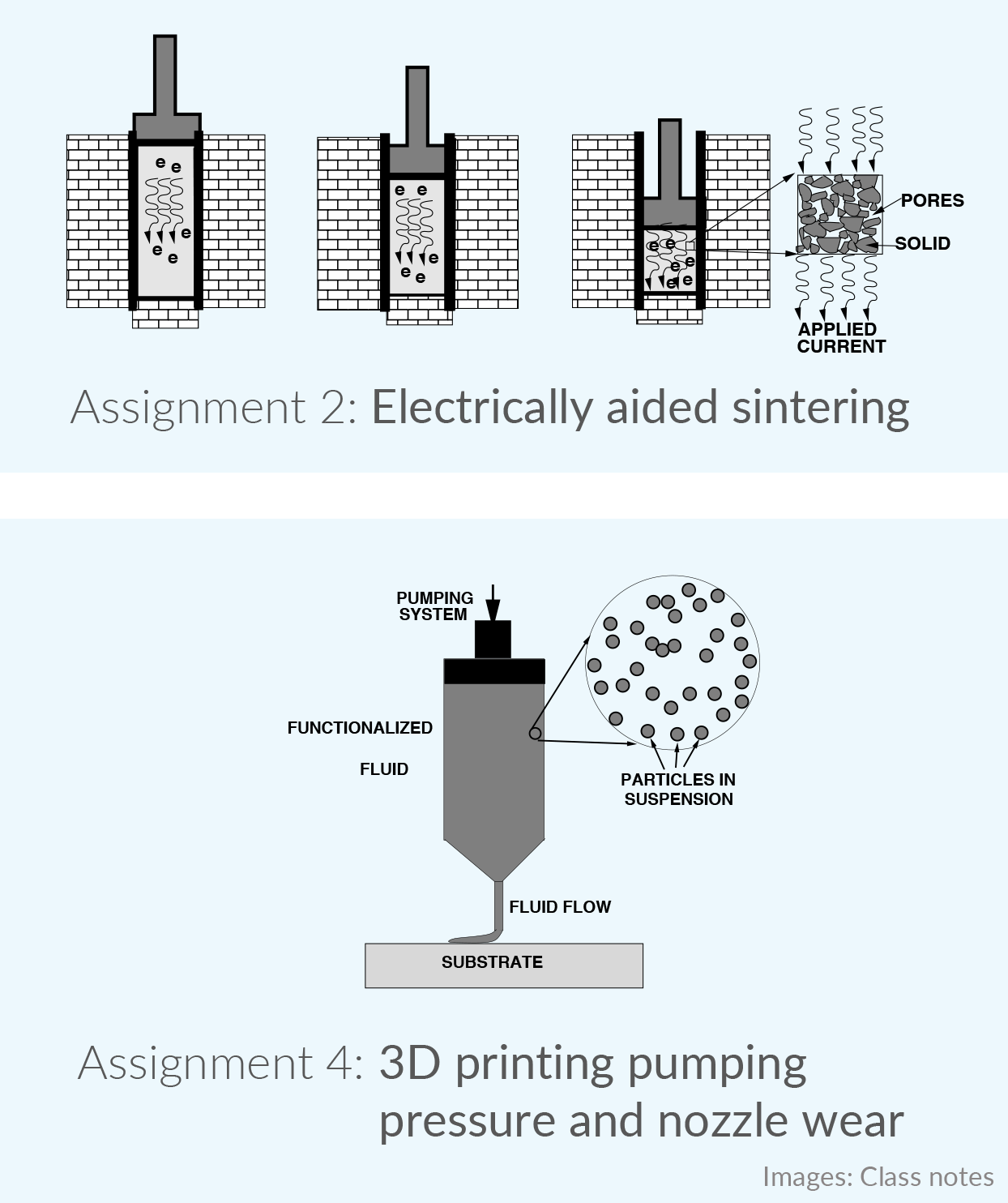

Simulation and Modeling of Advanced Manufacturing Processes

Semi-analytical modeling of manufacturing processes:

- Multiphysical modelling taking into account mechanics, material properties, heat, electricity, and magnetism

- Simplify complex equations by making qualified assumptions to make the math manageable

- Run time-stepping code to dynamically calculate and update all variables

This provides an in-depth intuition for the processes

Theory of Electron Microscopy and X-ray Diffraction

Electron Microscopy Laboratory

Two courses dedicated to microscopy, including a lab course with over 50 hours of TEM time

- Characterization of engineering materials by electron microscopy, diffraction, and spectroscopy

- Characterization of defects

- In-depth coverage of the theory of operation of a TEM in all diffraction and imaging modes

- Included over 50 hours of TEM time over the semester, in small teams of three.

Images obtained by tilting the TEM stage.

These images were used to produce a 3D reconstruction (see below).

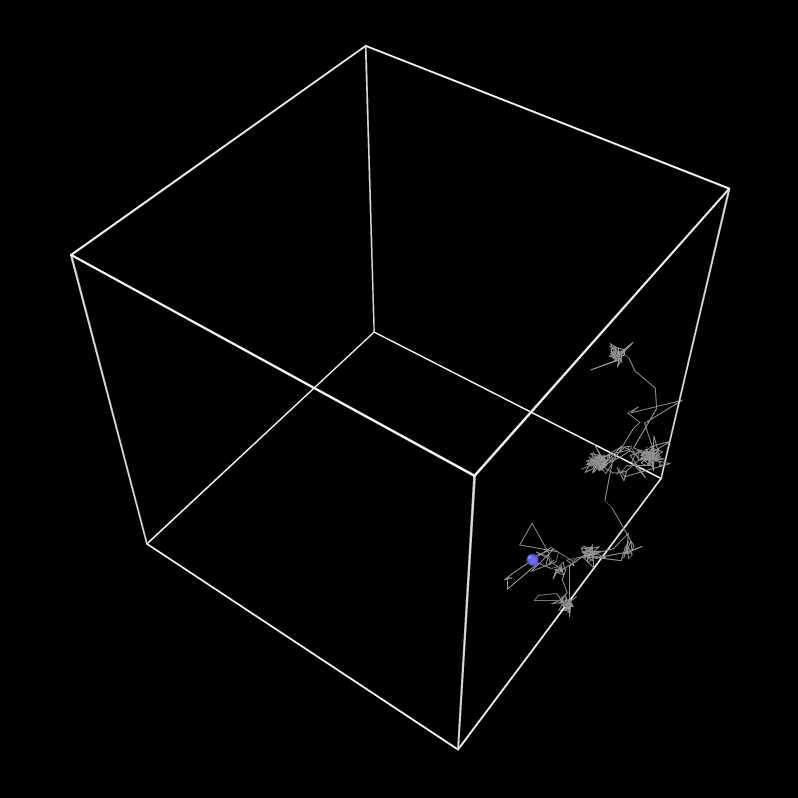

Video: Assignment, own work

Reconstructed 3D model.

Images across a larger range of angles will give a better reconstruction.

Video: Assignment, own work

Computational Materials Science

Introductory computational materials science course covering multiple computational techniques.

Spent one month each working on projects in

- Empirical energy methods

- Density Functional Theory (DFT)

- Monte Carlo Methods

- Molecular Dynamics

Diffusion of a Hydrogen atom in a matrix of Palladium, from a Molecular Dynamics simulation

System contains 500 Pd atoms and 10 H atoms in total. Temperature = 950 K. 50 ps run with a coordinate dump every 0.1ps.

Image: Assignment, own work

Mechanics of Solids

Elements of Solid Mechanics

UE 204

Two courses covering analytical and numerical treatment of mechanics of solids

- Axial, shear, and torsion of simple bodies

- Theory of simple bending, and stress distribution in beams

- Principal stresses and strains, Mohr’s diagram

- Energy methods, Principal of virtual work, and Castigliano’s theorem

- Continuum mechanics: stress and strain tensors, equilibrium, compatibility

- Three-dimensional elastic, plastic, and viscoelastic problems

- Thermal, transformation, and dealloying stresses

- Stress concentrations, plane problems, metal forming problems

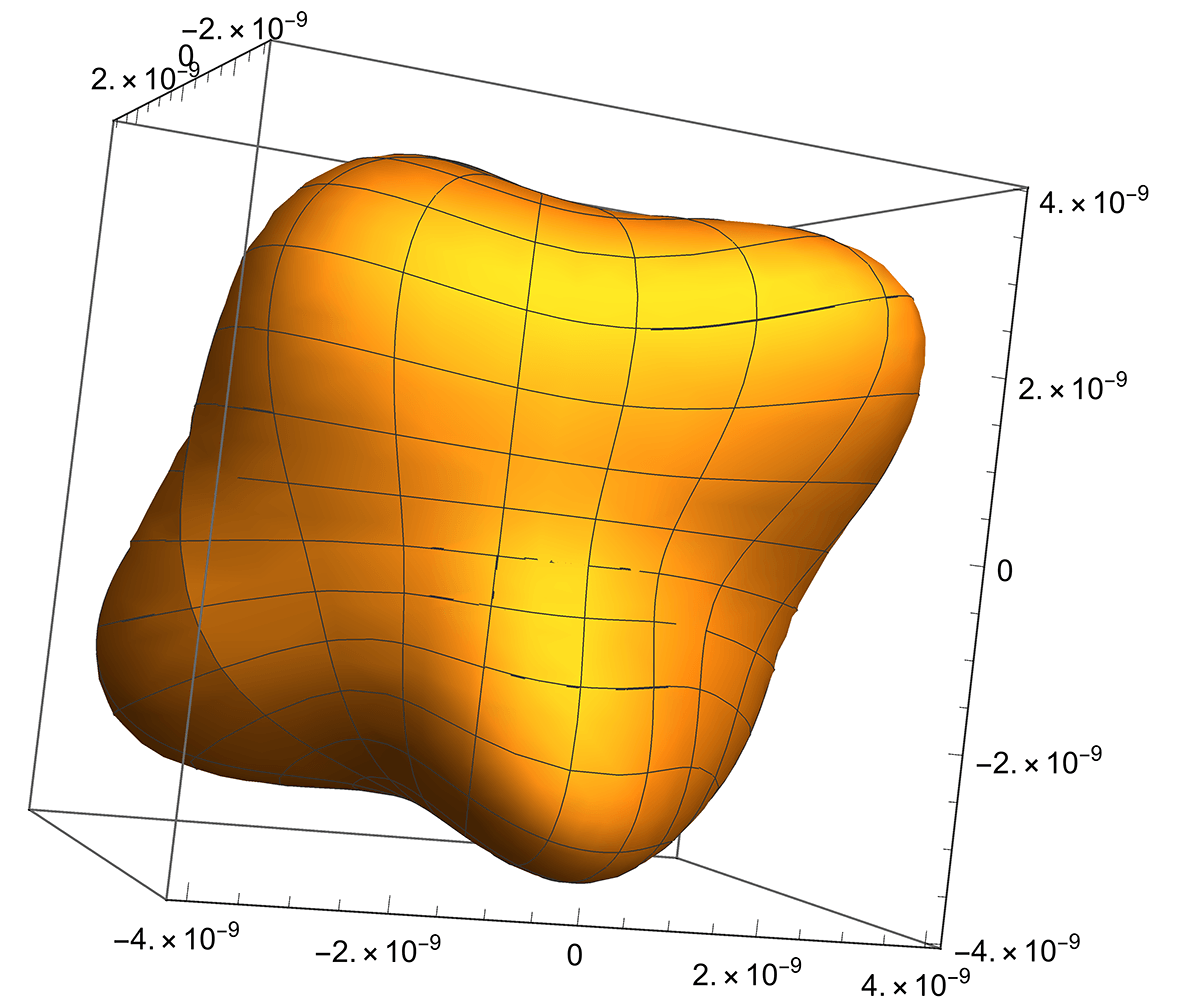

Anisotropic materials exhibit non-uniform properties in different directions.

This image shows Young’s modulus of Copper Sulphate as a function of sample orientation. Different orientations (with respect to the crystallographic axes) show different Young’s moduli

Image: Assignment, own work

Microstructural Design and Development of Engineering Materials

How can engineering materials be tailored to achieve the required properties?

- Importance of composition, process, and microstructure in the resultant properties of materials

- Covered: Aluminum alloys, Steels, Titanium alloys, Ni-base superalloys, and Magnesium alloys

- Discussed modifications due to alloying additions, heat treatment, ageing, tempering, phase control through processing conditions, etc.

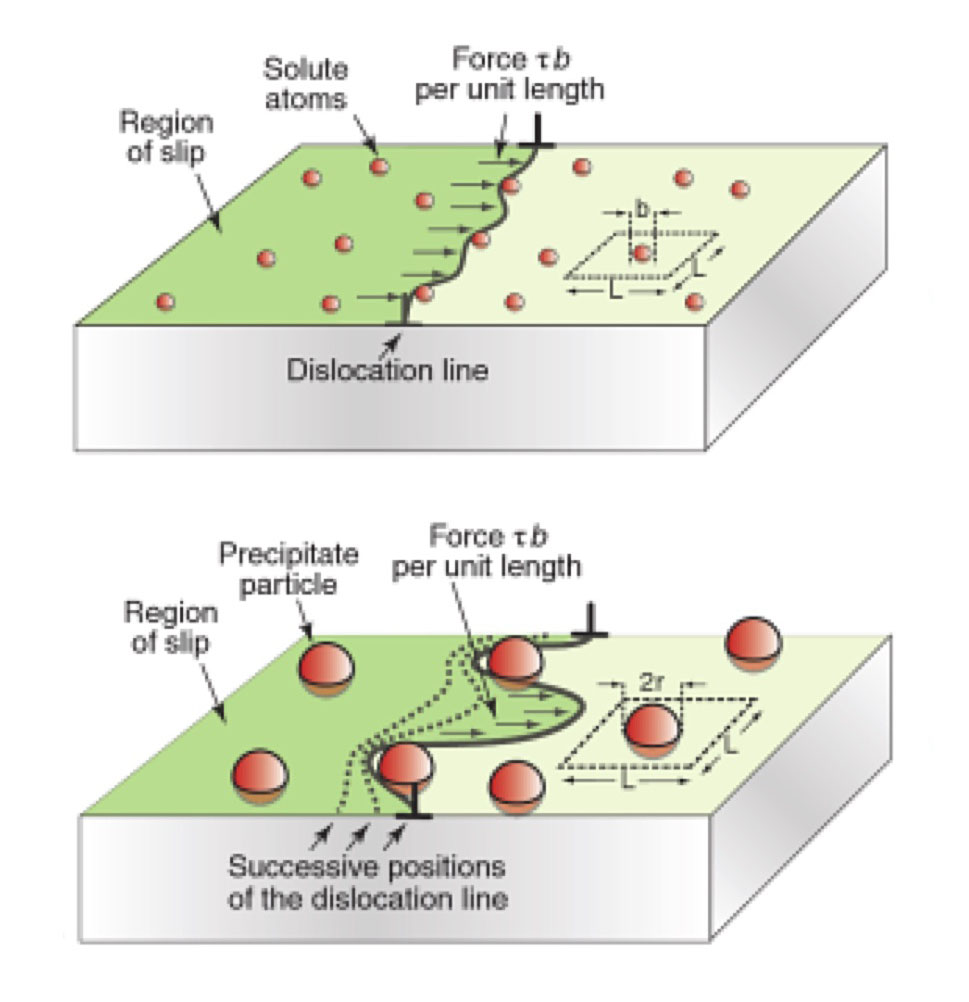

Strengthening due to solute atoms and precipitates.

Image: Class notes

Polymer Science and Engineering

Polymer blends and Nanocomposites

Polymer manufacturing and processing

Behaviour with blending and composite additions

- Chemistry and process aspects of manufacturing.

- Polymer processing including thermoforming, extrusion and injection moulding, and blow moulding.

- Behaviour of blends and composites with respect to viscosity, processability, mechanical properties, conductivity, etc.

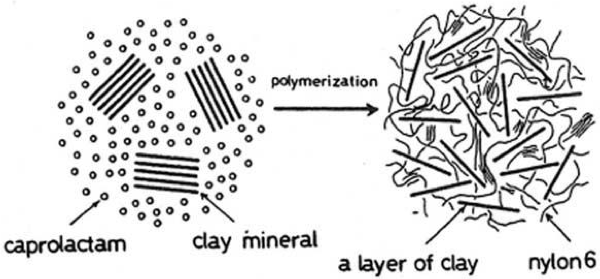

Nylon-6/clay nanocomposite

Used in the automotive industry since the late 1990s.

Image: Class notes

Materials Thermodynamics, Materials Kinetics,

Microstructures in Materials, Phase transformations

4 courses dedicated to core physical metallurgy

Covers:

- Diffusion

- Phase diagrams

- Microstructure evolution

- Sintering

- Nucleation and grain growth

and many other related topics

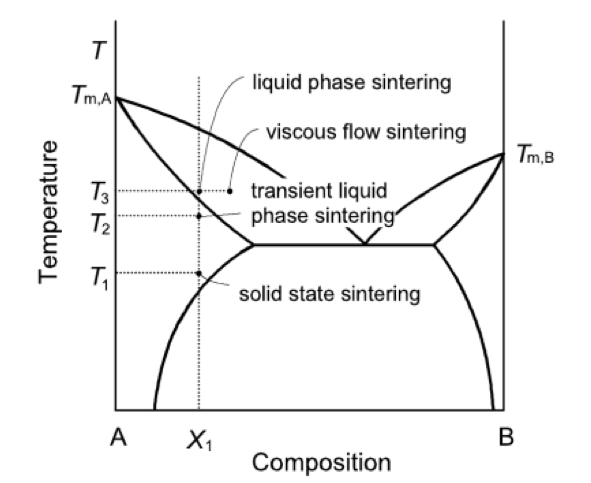

Sintering in different phase regions.

Image: Class notes

Solidification processing

Theoretical physics-based approach to solidification

- Segregation

- Gibbs-Thomson effect (dependence of segregation on size)

- Transport processes in solidification

- Instabilities, dendritic growth

- Eutectic and peritectic growth

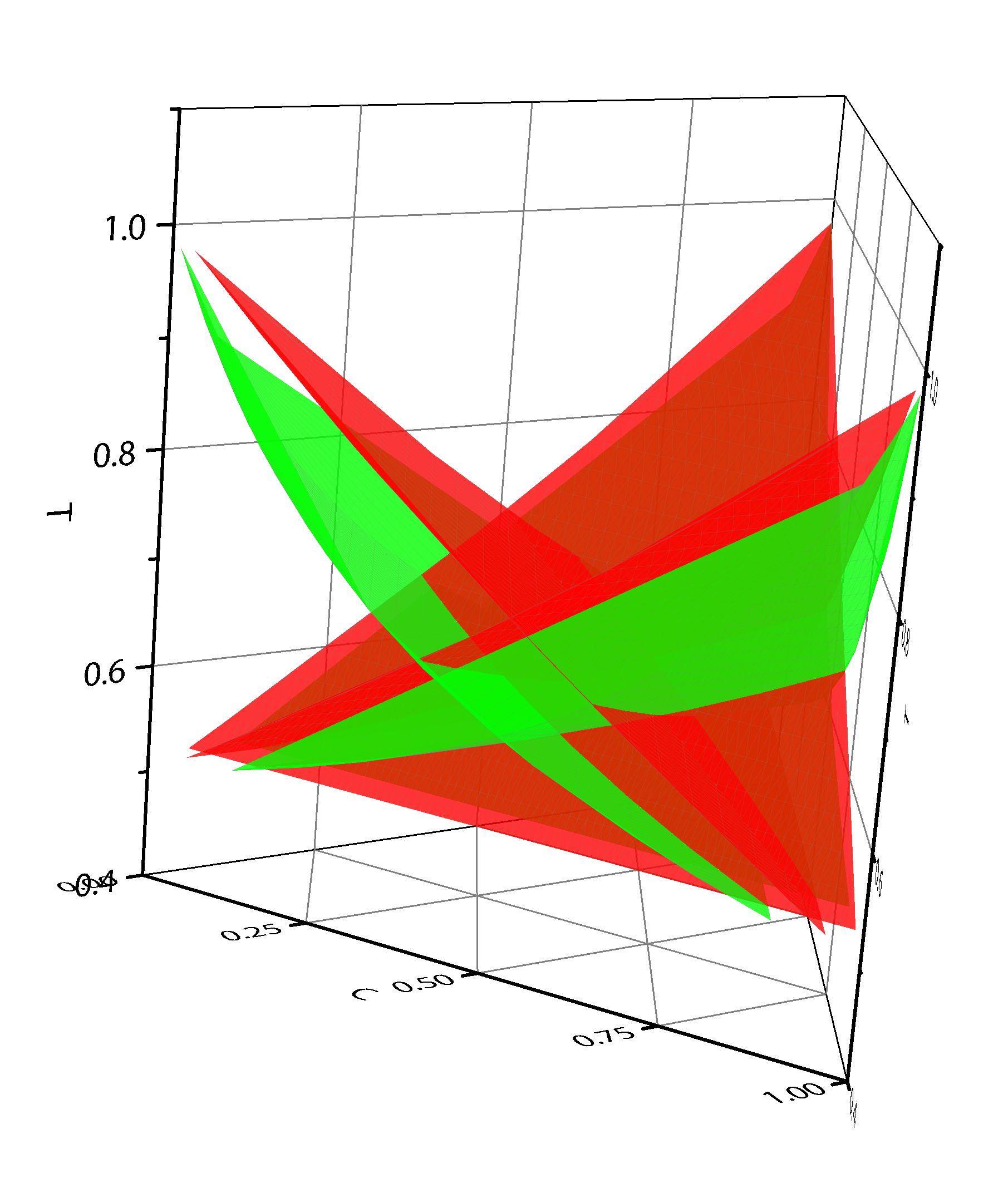

Ternary isomorphous phase diagram, calculated from differential equations using Gibbs free energies

Image: Assignment, own work

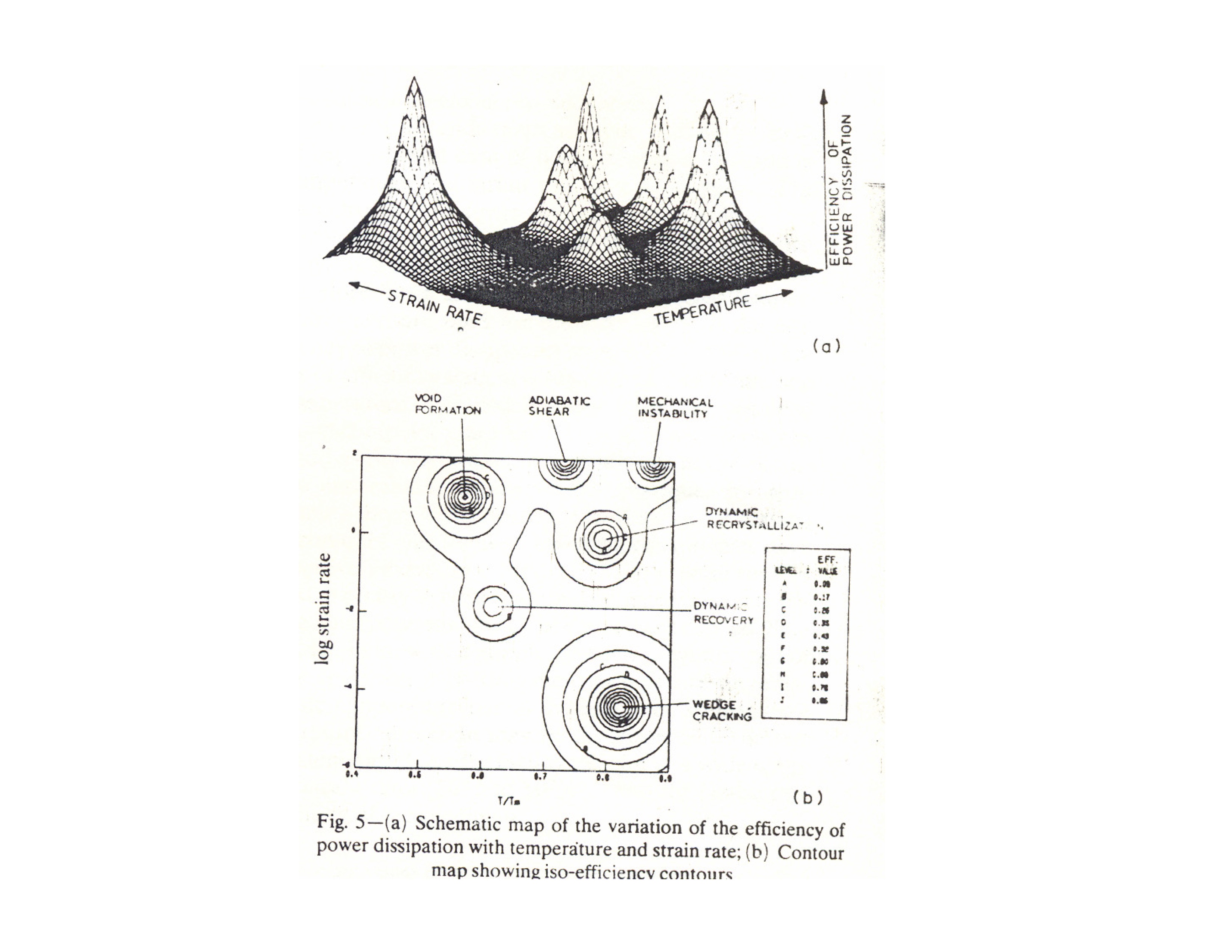

Science of Materials Processing

Main topics

- Deformation processes

- Powder metallurgy

- Process maps

Mechanisms covered:

- Plasticity, yield, flow instability, drawability, anisotropy

- Sensitivity to temperature and strain rate

- Thermally activated deformation

- Powder processing

Also covered: Casting and joining, welding, recovery and recrystallization, softening mechanisms

Process maps

Image: Class notes